-40%

Automatic Boston bottle filling and capping machine with Bottle feeding system

$ 18744

- Description

- Size Guide

Description

IntroductionApplication: 30 ml Cylindrical dropper bottles (glass&plastic)

Filling material: Liquids (MCT oil, cosmetic lotion, chemical detergents and oral liquids etc)

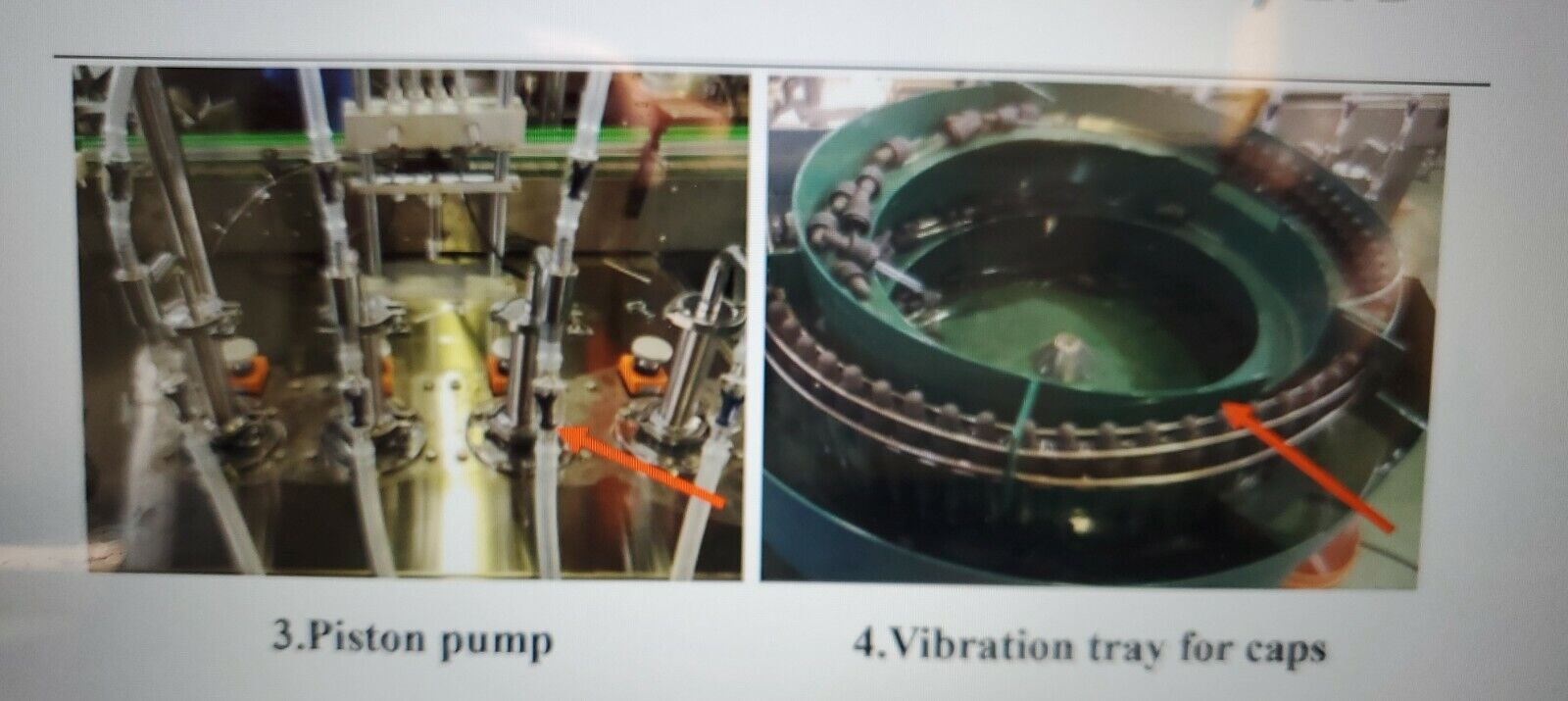

Filling method: Piston filling & self-sucking

Cap feeding way: Automatic vibrator (SUS304, polished treatment)

Working flow: Bottle feeding+automatic filling + automatic cap feeding +automatic

cap screwing + conveying out for packing/labeling

Features

Filling:

A Piston dosing system is adjustable for different filling capacity

B Teflon sealings

C Contact materials is SS316 and steel hose (food grade)

D No filling in the absence of bottle, preventing waste

E Nozzle down filling, preventing bubbles and sprinkles

Capping:

A Star wheel mould to fix bottle for steady cap screwing

B Automatic cap feeder, feeding speed up to 80pcs/min

C All parts in touch with the caps are covered with a soft silicon gel to

protect the cap from being scratched

Control:

PLC controlled + touch screen operation

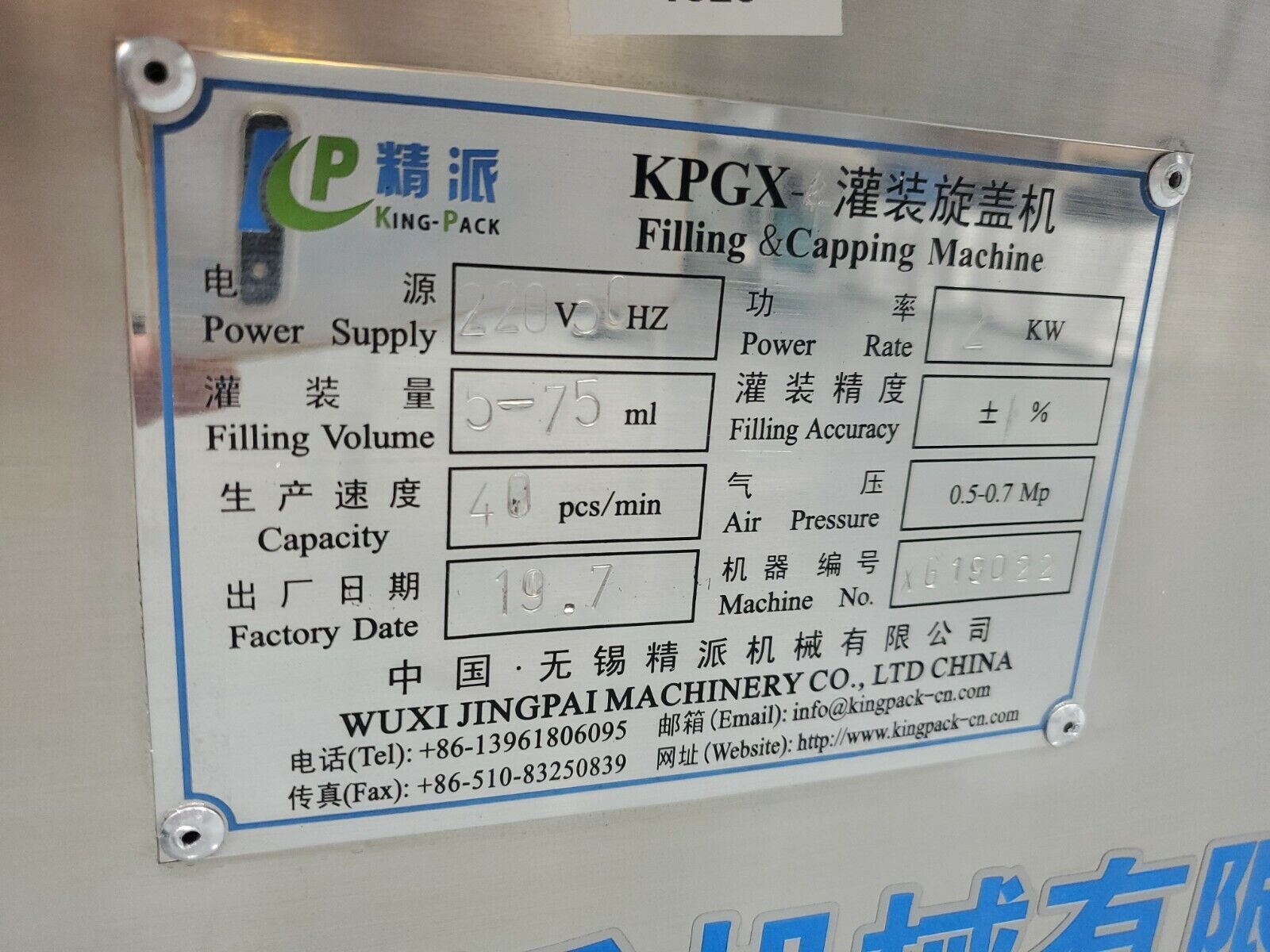

Technical Parameter

1 Total rate 2.5KW

2 Power supply 220V, 60Hz, 3P

3 Filling nozzle 4

4 Filling range 5-50ml

5 Filling error 1%

6 Working speed 20~30pcs/min

7 Air Consumption 0.3~0.5MPa

8 Dimension 2000mmx850x1650mm

9 Weight 450kg

Buyer can come to plant of Ingenuity beverages for checking the machine in person.